Comminution of P/M materials in a vertical vibratory mill

Vibratory Mill These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

WhatsApp)

WhatsApp)

Vibratory Mill These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

Vibratory Grinding Mills Size Reduction Equipment Specifically designed for wet grinding, the low amplitude VibroEnergy Grinding Mills range from ft#179; ( liters) to 113 ft#179; (3,200 liters) of volume. Wet Grinding Mill

#0183;#32;In vibratory mills, a spring mounted mill chamber is set into motion via a revolving unbalance and more specifically, an eccentrical drive. The mill chamber is usually operated either filled with a grinding media consisting of a large number of small spheres or rods or filled with few but large grinding bodies, which can be a combination of rings and a cylindrical core (disc).

SWECO, the world leader in particle separation and size reduction solutions, offers round and rectangular separators for dry material separation and sizing as well as liquid solid separation. Additionally, SWECO offers Gyratory Sifters, Pharmaceutical Aseptic Separators, Decanter Centrifuges and aftermarket parts and screens for multiple industries.

Jars, Ball, Pebble Mills amp; Vibratory Type Mills. Aadvanced Machinery offers a wide selection of attritors and paint mills used for particle size reduction, dispersion and particle size grinding and milling. We sell used and reconditioned attritors, bead mills, horizontal media mills, vertical media mills, and 3 roll mills.

Jan 11, 2016#0183;#32;This vibration is usually, but not necessarily, in a vertical plane. Vibration mills are similar to ball mills in that particles of the materials are crushed between porcelain or metal balls and the mill

The vibratory mill type as well as the correlation between the grinding bodies'' weight and size and the materials being ground have been examined to determine their influence on the particle size and the grinding factor when silicon and titanium carbides were ground in a vertical vibratory mill

General Kinematics VIBRADRUM#174; Grinding Mills are proven in dozens of milling applications in the mining and mineral industries.. Each grinding mill is achieving impressive energy savings (3550%),

Vibratory Ball Mill. Type No.: ZM1L Brand: TENCAN Applications: It is widely used in the fields of electronics, ceramics, chemicals, powder metal, tungsten, Calcium carbide, rubber compounds, magnetic materials and highfrequency porcelain material and pharmaceutical of radio industries.

Jars, Ball, Pebble Mills amp; Vibratory Type Mills. Aadvanced Machinery offers a wide selection of attritors and paint mills used for particle size reduction, dispersion and particle size grinding and milling. We sell used and reconditioned attritors, bead mills, horizontal media mills, vertical

#0183;#32;The schematic diagram of the vibratory ball mill: (a) vertical platform, (b) flat springs, (c) aluminium panels, (d) steel support panel, (e) hardened steel container, (f) hardened steel ball, (g) force transducer, (h) accelerometer and (i) charge amplifiers. h to 12 f(t) IB c h Is lc iii i e mg Fig. 2.

Vibration is a mechanical phenomenon whereby oscillations occur about an equilibrium word comes from Latin vibrationem (quot;shaking, brandishingquot;). The oscillations may be periodic, such as the motion of a pendulumor random, such as the movement of a tire on a gravel road.. Vibration can be desirable: for example, the motion of a tuning fork, the reed in a woodwind instrument or

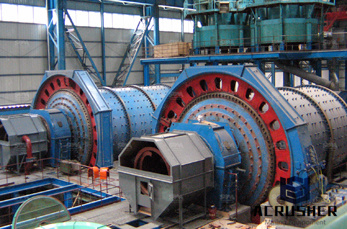

Recommended Products In The vertical vibratory mill spring. Sand Making Machine. It incorporates three crushing types and it can be operated... VSI5X Crusher. VSI5X crusher is necessary crushing

cement vertical mill is mainly used for grinding cement recent years, with the vertical mill design, manufacturing technology, grinding process innovation, vertical cement mill as cement grinding equipment, has been successfully applied in foreign annual production of cement vertical mill used in cement industry is 30, 60, 100, 120, and 1 million 500 thousand tons

#0183;#32;View this vibratory bowl feeder system with a spring detangler from Hoosier Feeder Company.

General Kinematics VIBRADRUM#174; Grinding Mills are proven in dozens of milling applications in the mining and mineral industries.. Each grinding mill is achieving impressive energy savings (3550%), thanks to a unique rotational material motion that is more efficient than conventional ball or rotary grinding mills. New processes such as micron grinding and mechanochemical grinding give our

WhatsApp)

WhatsApp)