Gold Refining Complete Process for the Home Refiner

#0183;#32;Starts with calculating to inquart the gold. Ends with melting a 999 fine gold bar. Demonstrates all the processes in between. Shows examples of equipment us...

WhatsApp)

WhatsApp)

#0183;#32;Starts with calculating to inquart the gold. Ends with melting a 999 fine gold bar. Demonstrates all the processes in between. Shows examples of equipment us...

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process. The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold.

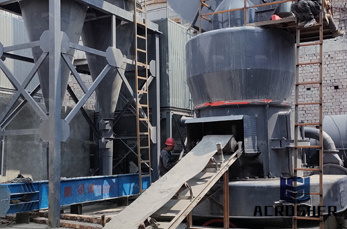

Gold Ore Processing Machine In Africa,Shanghai XSM is a professional ore crusher equipment,Gold Ore Processing Machine In Africa, mechanical beneficiation equipment, ore milling equipment mining process, the first belt conveyor, vibrating feeder, conveyor equipment ore sent to the jaw crusher, impact crusher, hydraulic crusher is a crushing raw ore, and the second by a

Gold can be concentrated and recovered by applying different gold refining process methods and the final product has variable quality. In this way, it is necessary to have a better marketable product so that the incomes can be improved. Then, we have two smelt and cast the gold into bars called bullion or Dore. The name bullion is restricted to the precious metals, refined or unrefined, in

Refining from scrap. The processing of gold scrap varies not only with the gold content but also with the amenability of the gold in the scrap to extraction. Thus, the bulk of the gold may be recovered by leaching techniques using cyanidation or aqueous chlorination, and the residue may then be treated by smelting to recover the balance.

#0183;#32;Discovered in 1886, it produced 25 percent of the worlds gold by 1899 and 40 percent by 1985. The discovery of the Witwatersrand deposit coincided with the discovery of the cyanidation process, which made it possible to recover gold values that had escaped both

Gold Ore Refining Process Flow Chart Ore Beneficiation Plant,Ore . Ball Mill Cost for 100 ton Cement Production Plant; Exxon gold ore refining processing machines including crusher,grinding mill,beneficiation plants for gold . Click amp; Chat Now

911MPE has small gold mining equipment for sale and more specifically mineral processing equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics. 911MPE offers gold mining equipment as well as processing equipment applicable to most any base metals: copper, lead, zinc, nickel, tin, tungsten

Gold Concentrate Processing Line Gold Ore Refining . After processing the original gold ore concentrate with a taste of 513 was upgraded to a gold ore concentrate with a gold content of 90 the main equipment of this project includes jaw crushers ball mills spiral classifiers flotation machines thickeners mixing tanks and many other equipment

Lowgrade ore is relatively simple to process while highgrade ore is a more extensive and complicated process. Completing OffSite Refining; Once the initial processing is done onsite, the gold is transported to an offsite refinery to undergo further refining. The purpose of this refining is to remove any remaining impurities. The crude gold

Gold extraction refers to the processes required to extract gold from its ores. This may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of small gold

offers 2,264 gold refining equipment products. About 28% of these are Mineral Separator, 5% are Mine Mill, and 2% are Other Mining Machines. A wide variety of gold refining equipment options are available to you,

#0183;#32;There is still gold in this underground mine! We have found a spot at our gold mine where the old miners left rich ore and we are going to get it out and cr...

#0183;#32;Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied. Oxide ore deposits are frequently of such low grade (, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified. In this case they are merely shattered by explosives and then piled into

offers 374 gold refining processing products. About 7% of these are other mining machines, 3% are oil pressers, and 1% are other food processing machinery. A wide variety of gold refining processing options are available to you, such as haccp, iso, and qs.

Gold Refining Machine Manufacturers In Tamilnadu. Our company mainly produces five series of products, including crushing equipment, sand making equipment, mineral processing equipment, grinding equipment and building materials equipment. 40 years of mining machinery manufacturing history, three production bases, exported to more than 160 countries and regions, We are your trusted

For the first time ever, gold processing can be done with a high level of confidence and safety, from a very small jewelry business to medium scale refinery. The process is simple and easy. By using our REFINEIT system, all the user has to do is melt the gold in an ingot, submerge the gold in the gold refining equipment we provide, then wait.

Gold ore Process in Australia,crushing and mill in Concentrator. Mining Equipment; Optional Equipment presents a simplified flow diagram of various gold ore perth mint). the perth mint refining process involves melting of the gold

WhatsApp)

WhatsApp)