Coke (fuel) Wikipedia

Uses of Coal Industrial and Domestic Uses of Coal

WhatsApp)

WhatsApp)

Uses of Coal Industrial and Domestic Uses of Coal

#0183;#32;Coal provides just over a quarter of the worlds primary energy needs, with thermal coal generating about 40% of the worlds electricity, whilst almost 70% of the worlds steel industry is dependent on coal for either coke production or for coal injection, either via what is known as the integrated route, or as the energy/reductant source in direct reduction processes.

Coal fired power plants are a type of power plant that make use of the combustion of coal in order to generate use provides around 40% of the world''s electricity and they are primarily used in developing countries. Countries such as South Africa use coal for 94% of their electricity and China and India use coal for 7075% of their electricity needs, however the amount of coal

#0183;#32;Coal reserves are available in almost every country in the world. The biggest reserves are in the USA, Russia, China and India. Peat deposits are quite varied and contain everything pristine plant parts (roots, bark, spores, etc.); Coal is responsible for 89% of all carbon dioxide emissions from the production of electricity.

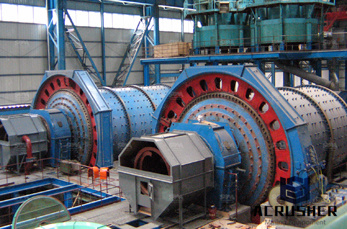

#0183;#32;Coking coal is used in largescale industrial processes. The coal is coked, a process of heating the rock in the absense of oxygen. This reduces the moisture content and makes it a more stable product. The steel industry relies on coking coal.

Many industries use coal to manufacture certain products. Some of the popular industries which make use of coal are the cement industry, paper and aluminium industry, chemical and pharma industry amongst others. Coal provides numerous raw materials like benozle, coal tar, sulphate of ammonia, creosote, etc. to chemical industries.

An industrial coal blend was carbonized at the ENSIDESA industrial coking plants at 1230 and 1280 #176;C (T1 and T2) and at the INCAR coking test plant at 1180, 1220 and 1280 #176;C (T3, T4 and T5), respectively. The same coal blend was also preheated at 214 #176;C and then carbonized at 1200 #176;C (T6).

Coal is a heterogeneous fuel and has only an assumed structure of C amp; H and varies highly from mine to mine and even in the same mine from seam to seam. C amp; H in coal can be known only after carrying out ultimate analysis moreover the way in which these hydrocarbons will behave will depend upon their reactivity and how that coal is formed.

Industrial coal coke briquette making process, briquetting . What is the industrial coal coke briquette The industrial coke is made of pulverized coal as raw material, processed by coals blending (or single coal) and then briquetting to briquette, after that through the coking process gets the coke and coketype coal

Coal gasification is the process of producing syngas a mixture consisting primarily of carbon monoxide (CO), hydrogen (H 2), carbon dioxide (CO 2), natural gas (CH 4), and water vapour (H 2 O)from coal and water, air and/or oxygen. Historically, coal was gasified

Coal is a combustible black or brownishblack sedimentary rock, formed as rock strata called coal is mostly carbon with variable amounts of other elements; chiefly hydrogen, sulfur, oxygen, and nitrogen. Coal is formed when dead plant matter decays into peat and is converted into coal by the heat and pressure of deep burial over millions of years.

Facts about Coal Mining in the Industrial Revolution inform you with the mining process as well as the importance of coal during the industrial revolution. Before 1700, actually the British people tried to get coal located at the surface area. Coal was considered as the important energy for the steam engine could be operated using coal.

#0183;#32;During the period of the industrial revolution, as demand for coal soared thanks to iron and steam, as the technology to produce coal improved and the ability to move it increased, coal experienced a massive 1700 to 1750 production increased by 50% and nearly another by 1800. During the later years of the first revolution, as steam power really took a firm grip, this rate

#0183;#32;Although the United States has the vast coal resource described in the previous chapter, perhaps as much as 4 trillion tons, the key issue for policy makers is the amount of coal that is economically is not a fixed quantity, but depends on the geological resource, the market price, and the cost of mining. The particular characteristics of the coal mining industry create unique

Coal combustion technology has been further developed since the late nineteenth century. The coal fixedbed stoker system was invented in 1822; the firing of pulverized coal occurred in the brickkiln in 1831, and fluidizedbeds were invented in 1931. Nowadays, direct coal combustion is extensively utilized for industrial and domestic

been using coal since the early 1300s for cooking and heating, but it was not utilized to its fullest extent until the start of the Industrial Revolution in the 1800s when electricity became a necessity (Coal''s Past, Present, and Future, 2010). Through the coal burning process, coal creates electricity which is put to use by the world. Get Price

industrial process of coal . industrial process of coal . Coal Wikipedia, the free encyclopedia. edit]. Finely ground bituminous coal, known in this application as sea coal

largely responsible for the growth in coal use. The history of coal mining and use is inextricably linked with that of the Industrial Revolution iron and steel production, rail transportation and steamships. Coal was also used to produce gas for gas lights in many cities, which was called town gas. This process of coal gasification

Underground Coal Gasification is an industrial process by which coal is gasified in situ. This process converts the physical coal to a product gas (a type of... Learn More . The Carbochemical industry world Industrial Qu#237;mica del Nal#243;n.

WhatsApp)

WhatsApp)