:

For an aircooled slag at optimized conditions, 72% of copper was recovered in one stage flotation and a % copper concentrate was achieved. The best recovery efficiency was obtained when 30 g...

WhatsApp)

WhatsApp)

For an aircooled slag at optimized conditions, 72% of copper was recovered in one stage flotation and a % copper concentrate was achieved. The best recovery efficiency was obtained when 30 g...

An appreciable amount of copper is slagged in highgrade matte smelting and converting. The major part of copper lost in slag is recovered through slagcleaning operations. Copper losses in slag ar...

The main waste waste rocks, flotation tailings and slag from mining and metallurgy of copper, are often rich in metal content, and sometimes an even richer source of metals than natural ores. Therefore, different possibilities to recover metals from waste 90 have been examined.

PDF | The flotation behaviour of a complex nonferrous slag, which contained tin, lead and copper, as well as willemite, galena and sphalerite,... | Find, read and cite all the research you need

Aiming at the recovery of copper from smelting slag, a flotation approach was studied. It was found that this slag composed of fine particles with complex association and distribution, in which bornite was the main copperbearing mineral after a detailed mineralogy analysis via polarizing microscope, SEM and XRD.

Nov 30, 2008#0183;#32;This study reports the potential use of flotation waste of a copper slag (FWCS) as iron source in the production of Portland cement clinker. The FWCS appears a suitable raw material as iron source containing gt;59% Fe(2)O(3) mainly in the form of fayalite (Fe(2)SiO(4)) and magnetite (Fe(3)O(4)).

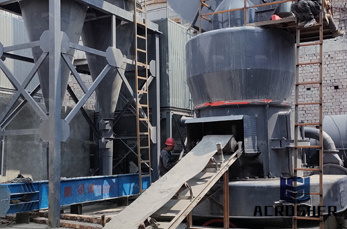

Vertical mill for copper slag processing is usually utilised to supply the heat stove, drying and grinding to achieve the procedure of slag, slag qualified library in to the slag. Save slag dryer, simplifying the production approach. Copper slag flotation plant. The copper slag flotation machine was developed for mineral processing by flotation.

4 Budapest, November 2830, 2016 28th NOVEMBER cond grinding stage of copper slag processing at Bulgaria V. Stoilov, et al. Aurubis Bulgaria, Bulgaria 11:50 The treatment of complex copper ores by flotation potentials for improvements W. Bernhart Ingenieurb#252;ro f#252;r Bergwesen und Verfrenstechnik, Austria 12:15 LUNCH

Froth flotation is a process for selectively separating hydrophobic materials from is used in mineral processing, paper recycling and wastewater treatment industries. Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th century.

Currently, the slags are sent to a milling and flotation plant for liberation and recovery of residual copper. The copper recoveries realized in the plant are much lower than expected and it has been postulated that some copper minerals may be occurring in forms that are more difficult to float like oxides or fine disseminations in the gangue matrix.

Jan 01, 2020#0183;#32;Various flotation reagents that are commonly used for copper flotation were identified, selected and used during the flotation test work in order to identify the best reagent best suited to float the copper slags. Potassium amyl xanthate (PAX) and Flotanol CO 7 were used in all tests as the primary collector and frother.

approximately 12 million tons of copper slag is produced every year, and the amount of accumulated waster copper slag reached 140 million ton by 2015 in China [6]. Generally, copper slag contains about 3545 wt. % iron and wt. % copper, indicating that it is a valuable secondary resource for recycling and utilization [3].

Jan 01, 2018#0183;#32;In this study, the effects of [+] and [+] on the sulphidizing and flotation of copper oxide in copper smelting slag are systematically investigated based on the analysis of chemical composition and phase of copper smelting slag. The interaction mechanism of the [+] and [+] on the copper oxide surface is studied.

related. The list of abbreviations related to FWCS Flotation Waste of Copper Slag

It is a step of the processing of certain specifically, roasting is a metallurgical process involving gassolid reactions at elevated temperatures with the goal of purifying the metal component(s). Often before roasting, the ore has already been partially purified, by froth flotation. Send Inquiry

Some properties of a typical copper slag are shown in Table I, and it can be observed that aircooled copper slag has a black colour and glassy appearance. The specific gravity varies with iron content, from to The unit weight of copper slag is somewhat higher than that of conventional aggregate. The absorption capacity of the

Flotation waste of copper slag (FWCS), neutralization sludge (NS), and arseniccontaining gypsum sludge (GS), both of which are difficult to dispose of, are major solid wastes produced by the copper smelting. This study focused on the cotreatment of FWCS, NS, and GS for solidification/stabilization

The slags cannot be discarded due to the high content of copper and hence they are sent to a milling and flotation plant (Slag Mill Plant) for liberation and recovery of copper. This work focuses on optimizing the recovery of copper minerals in copper smelter slags by means of froth flotation.

Meeting in Budapest discusses utilization of C156 Leaching behaviour of copper converter slag obtained under different cooling conditions Dos et al. C163 Technical notes Method of automating semibach flotation 129 Evaluation of flotation collectors for copper

copper flotation machine for mica in ethiopia. principles of froth flotation springer link. of silt in ponds by ethiopian women who used goose feathers covered with bitumen to pick mineral processingprinciples 0/ froth flotation pulp from in elmore patented methods in

WhatsApp)

WhatsApp)