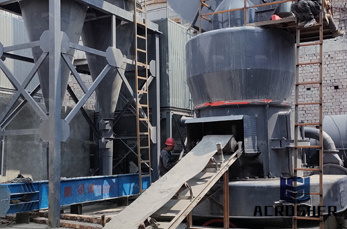

China Rolling Mill Hot Steel Wire Rod Wire Rod Coil

China rolling mill find detail hot steel wire rod, wire rod coil from taiyuan rely trade co., ltd.

WhatsApp)

WhatsApp)

China rolling mill find detail hot steel wire rod, wire rod coil from taiyuan rely trade co., ltd.

The cooling rate of high carbon steel wire rod after wire rod rolling mill rolling is too fast, which may also cause cracks in finished products, and the latter can also cause transverse cracks. Cracks formed by improper controlled cooling after rolling are not accompanied by decarbonization, and there is generally no oxide scale in the cracks.

Our Hot Rolling Mill Solutions Includes: Wire Rod Rolling Mill UpTo 600,000 Tons Per Year With High Speed Rolling Technology | ReBar Rolling Mill UpTo 1,000,000 Tons Per Year With Slit Rolling Technology | Light Section Rolling Mill / Structure Rolling Mill amp; Heavy Section Rolling Mill Up to 700,000 Tons Per Year | Steel Rolling Mill

Ivaco Rolling Mills offers a wide variety of hot rolled Wire Rod and continuous cast Steel Billets. Our products are engineered to endure the most demanding applications in the industry, and are clearly recognized for their high quality and reliability.

Wire Rod Rolling Mill is available at pocket friendly prices in the market. Further Details: UGI wire amp; rod mill are known for their striking attributes such as reliable quality, excellent productivity, and efficiency.

Aug 13, 2015#0183;#32;Uniform heating of billets and tension control during hot rolling are generally used to achieve the required dimensional accuracy, since in practice it is difficult to guarantee closer tolerances by conventional wire rod mills over extended production periods. In the wire rod mills, it is normal to use rolls with grooves.

Mar 20, 2019#0183;#32;The morgan finishing mill/wire rod mill arranged after the flying shear area and before the cooling device. Its role is to continuously micro tension rolling by 8 rack unit, the rolled piece ~ of rolling mill upstream delivery, rolled into ~ 16mm finished wire rod. Unit to ensure the exit speed of 90m / s.

Jul 08, 2019#0183;#32;Wire rod is made by drawing hot metal through shafts. The shafts form and compress the metal from different sides, thus turning a piece of metal into a long, thin wire. At the end of the rolling mill, this wire is wound on a special winder, with the help of which the

Typical products are rectangular copper wire for electrical equipment, lowcarbon steel ribbon for BX cable, nickelchrome flat wire for heating elements and highcarbon wire for springs. Mills operate at speeds exceeding 3500 fpm and are available in single or multiple stands. Wire capacities range from a few microns to 20 mm. Tandem Rod Mills

Our Hot Rolling Mill Solutions Includes: Wire Rod Rolling Mill UpTo 600,000 Tons Per Year With High Speed Rolling Technology | ReBar Rolling Mill UpTo 1,000,000 Tons Per Year With Slit Rolling Technology | Light Section Rolling Mill / Structure Rolling Mill amp; Heavy Section Rolling Mill Up to 700,000 Tons Per Year | Steel Rolling Mill Stands

The wire rod mill / finishing mill is situated in highspeed wirerod workshop. Finishing mill unit is combined with 10 mills, three #216;200 mills and seven #216;150 mills, speed increasing box, support base,arc coupling, waterproof slot, waterproof plate, buffer tank, the protective cover, coupling, piping and guide of finishing mill.

Secondary scale on hot strip and the impact on wear is another issue. Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later. K. H. Schr#246;der July 2003 K. H. Schr#246;der: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS

Wire rod mills TRIMROB ROBOTIC SYSTEMS AUTONOMOUS COIL TRIMMING AND SAMPLING FOR WIRE ROD MILLS MAIN BENEFITS Improved safety and reduced operator The TrimRob has no affect on the rolling mill process unlike a high speed trim shear which typically needs to be situated in the waterbox line before the laying head.

The corporate upholds the philosophy of quot;Be in excellent, be rooted on credit rating and trustworthiness for growthquot;, will keep on to serve outdated and new clients from home and abroad wholeheatedly for Wire Rod Hot Rolling Mill, Roughing Roll, Induction Furnace Frequency, Iron Rod Processing Line, We also ensure that your selection will be crafted with the highest quality and reliability.

steel bars and wire rods are manufactured in a wide variety of grades. Thus, they are characterized by small volume production in various sizes and grades. At the Mill, wire rods ( to 34mm ) and bars (22 to 62mm ) are rolled by one strand. Wire rod is finishrolled by a notwist mill (NT mill) and wound by a laying head. A thicker wire rod

not only to new wire rod mills, but also to revamping, modernisation and expansion projects. SPEED MEETS FLEXIBILITY Singlestrand highspeed wire rod mills from SMS Meer roll small sizes with high production rates up to 120 m/s are possible. Even at full speed, the mills achieve a very good laying pattern, while tempera

Bar and wire rod mills Hot Rolling. SMS group Website Plants All Plants Bar and wire rod mills. CUSTOMDESIGNED SOLUTIONS FOR A WIDE RANGE OF PRODUCTS. What''s special about our bar and wire rod mills is not only their high flexibility, but also their proven reliability. There is an array of products our stateoftheart mills can manufacture

Dec 18, 2020#0183;#32;Global Bar and Wire Rod Rolling Mills Market 2020 key application, opportunities, demand, status, trends, share, forecast 2026 Dec 18, 2020 reportocean The Global Bar and Wire Rod Rolling Mills Market research study is latest publication by Report Ocean that explains about the market along with competitive insights, market

The morgan finishing mill/wire rod mill arranged after the flying shear area and before the cooling device. Its role is to continuously micro tension rolling by 8 rack unit, the rolled piece ~ of rolling mill upstream delivery, rolled into ~ 16mm finished

WhatsApp)

WhatsApp)