Blast Furnace Clinker amp; Slag Processing Equipment in the

Blast Furnace Clinker amp; Slag Processing Equipment in the United Kingdom: Market Sales (English Edition) eBook: DataGroup UK, Editorial: : Kindle Store

WhatsApp)

WhatsApp)

Blast Furnace Clinker amp; Slag Processing Equipment in the United Kingdom: Market Sales (English Edition) eBook: DataGroup UK, Editorial: : Kindle Store

Blast furnace converter slag handling. Location: The Netherlands Industry: Bottom Ash (converter slag) Capacity: 100700 t/h. Scope: Turnkey processing plant for blast furnace converter slag. The systems includes bunkers, belt conveyors, crushers, screening equipment, overbelt magnets, vibrating feeders and truck loading units.

Location: The Netherlands Industry: Bottom Ash (converter slag) Capacity: 100700 t/h Scope: Turnkey processing plant for blast furnace converter slag. The systems includes bunkers, belt conveyors, crushers, screening equipment, overbelt magnets,

#0183;#32;Since receiving a patent for the processing of fiery liquid blast furnace slag, Severstal has processed about million tonnes of blast furnace slag at the

and effective means of processing blast furnace slag in the world today is rated as Best Available Technology. Flexibility of the INBA system The system provides you with an installation of high flexibility, independent from blast furnace operations, such as tapping time duration, intercast gap time, slag flow rates and many more.

These products include aircooled blast furnace slag (ACBFS), expanded or ed slag, pelletized slag, and grand granulated blast furnace slag (GGBFS) among which ACBFS and GGBFS are the most common ones. 5,6 Aircooled iron slag is used primarily as aggregates in concrete, asphaltic paving, fill, and road bases as well as a feed for cement kilns. 7 Almost all GGBFS is used as a partial

The invention relates to metallurgy, in particular to the processing of waste blast furnace and open hearth furnace slag. A method of refining molten blastfurnace slag by granulation [1. str316]. The method consists in obtaining granulated blast furnace slag by draining melt down an inclined plane into a pit of water, when this water is pumped into a pit on the same inclined plane.

#0183;#32;A blast furnace is a block that smelts ores and metal armor and tools, similar to a furnace, but at twice the rate. It also serves as an armorer''s job site block. 1 Obtaining Breaking Natural generation Crafting 2 Usage Smelting Light source Custom name Change profession Lock Note Blocks 3 Sounds 4 Data values ID Block states Block data 5 History

Blast furnace | metallurgy | Britannica

Briefly, blast furnace slag is formed when iron ore or iron pellets, coke, and a flux (such as limestone, CaCO 3, or dolomite, CaCO 3 #183;MgCO 3) are melted together in a blast furnace. When the metallurgical smelting process is complete, the lime in the flux has been chemically combined with the aluminates and silicates of the ore and coke ash to form the nonmetallic blast furnace slag.

Blast furnaces have grown considerably in size during the twentieth century. In the early days of the twentieth century, blast furnaces had a hearth diameter of 45 m and were producing around 100,000 THM per year, mostly from lump ore and coke. At the end of the twentieth century the biggest blast furnaces had between 14 and 15 m in hearth diameter, and were producing 34 million tons of

#0183;#32;To evaluate if glass can be replaced by blastfurnace slag Ding et al. stu died the effects of blastfurnace slag on properties of glass ceramic s. They add

Blast furnace watercooled slag (BFWS) has been solidified using a hydrothermal processing method, in which the BFWS could be solidified in an autoclave under saturated steam pressure ( MPa) at 200 #176;C for 12 h by the additions of quartz or coal flyash. The tensile strength development was shown to depend on the formation of tobermorite and the packing state of the formed tobermorite in

Separator Magnets. Walker engineers and manufactures magnetic pulleys, drums, Magnets are available for the automatic continuous separation and upgrading of ferrous from nonferrous metals in scrap processing, steel bearing slag, ound granulated blast furnace slag world market;

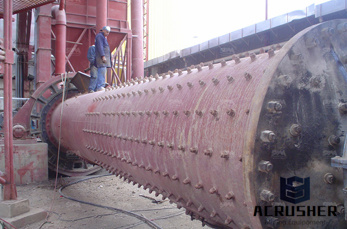

Complex for Crushing and Sorting (slag metal production) Sourcematerial specification. The line is designed for following source material parameters: Material to be processed: blast furnace slag; Mass volume: not defined, supposed to be tons / m3; Bulk material weight: from to tons / m3; Resistance to pressure: from 60 to 100 MPa

The finer fractions contain socalled magnetic slag, these are nuggets consisting of mineral and metal. Magnetic slag can be best separated with a 1,800 or 3,000 gauss head roller magnet. Using the band speed and the position of the separation bulkhead, the grade of

The Slag Furnace is a block added by works similarly to the vanilla furnace, but has an extra output slot. It also uses twice the fuel. For most ores, it will produce an ingot with a low (20%) chance of making two instead of one, and also some Stone. Silver Ore will make Silver Ingots and Lead is used for Mirrors, which are needed to make Factorization Charge

2 #0183;#32;Blast furnaces produce pig iron from iron ore by the reducing action of carbon (supplied as coke) at a high temperature in the presence of a fluxing agent such as blast furnaces consist of several zones: a crucibleshaped hearth at the bottom of the furnace; an intermediate zone called a bosh between the hearth and the stack; a vertical shaft (the stack) that

Blast furnace slag (BFS) is one of the waste streams being addressed by the BREW Waste Protocols Project. A Technical Advisory Group (TAG) was set up to bring together representatives from the Environment Agency, WRAP and industry. Appendix A contains a list of TAG members and Appendix B gives its terms of reference.

WhatsApp)

WhatsApp)