pre grinding impact for cement plant

A Review On Environmental and Health Impacts Of Cement Manufacturi

WhatsApp)

WhatsApp)

A Review On Environmental and Health Impacts Of Cement Manufacturi

Cement Manufacturing. 277. Air Emissions. A maximum emissions level of 50 milligrams per normal cubic meter (mg/Nm. 3), equivalent to a maximum of kg/t of clinker, for particulates in stack gases under fullload conditions is to be achieved. This emissions level is based on values that are routinely achieved in wellrun plants.

A cement company or cement plant should already be prepared for such a scenario as plants cannot be reliant on any individual. Knowledge needs to be captured in documented procedures and human capital needs to be developed via training and succession planning, such that there is

The cement grinding is an energy intensive process. The addition of grinding aids, during the process of cement grinding, results in improvement of the specific surface and grindability index of . Get Price; design vertical grinding mill with roles Mineral . Apr 20, 2016Grinding Ball Mill Machine Price,Bauxite Ball Mill Manufacture For .

#0183;#32;Grinding is the next step in the cement manufacturing process, and it can occur in either wet or dry forms. Wet grinding involves combining all of the materials in a mill with water and grinding it into slurry. In contrast, dry grinding processes combine and grind the materials without water, creating a substance known as kiln feed.

CEMENT AND LIME MANUFACTURING APRIL 30, 2007 2 WORLD BANK GROUP IndustrySpecific Impacts and Management The following section provides a summary of EHS issues associated with cement and lime manufacturing, which occur during the operational phase, along with recommendations for their management. Recommendations for the management of

Foul smell is sometimes a direct result of the gases emitted during cement manufacturing. Moreover, since cement manufacture has life threatening impacts to plants and animals, the

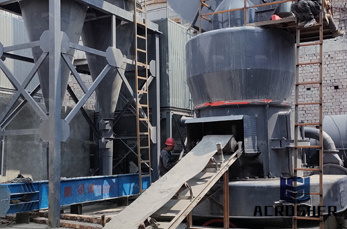

Grinding Impacts During Cement Manufacturing. Cement Grinding cement grinding is the final stage in Portland cement manufacturing. In this step, clinker will be ground in grinding mill to reach the qualified fineness of cement product. During the grinding, we usually add gypsum, fly ash and other raw materials into the cement to realize the different usage of cement.

Grinding aids work mainly by dispersing ground cement particles to avoid agglomerates, enabling an increase in production of up to 25 per cent. 1 In vertical roller mills, they can additionally be used to reduce vibrations and the amount of water injection, and thereby improve cement quality. 2

In the wet process, water is added during grinding. This review examines various impacts of Cement manufacturing companies on Environmental and Health aspects, by .

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Grinding aids, strength enhancers and quality improvers are based on chemical products. Grinding aids work mainly by dispersing ground cement particles to avoid agglomerates, enabling an increase in production of up to 25 per cent. 1 In vertical roller mills, they can additionally be used to reduce vibrations and the amount of water injection, and thereby improve cement quality. 2

Effect of grinding aids on closed circuit cement grinding As introduced before, grinding aids are sprayed in the mill, or added on the clinker, with dosages usually ranging from 100200 g up to 23 kg per ton of cement. Once a grinding aid is added during cement manufacturing, the main effect is the reduction of separator reject: more

Economic Impacts During Construction 15 Economic Impacts During Operation 15 For EIAs for cement manufacturing plants, members of, or advisers to, the noise during milling/grinding packing (high pressure packing) emergency and contingency

This is the solution for grinding aids sika can offer. Grinding aids, strength enhancers and quality improvers are based on chemical products. Grinding aids work mainly by dispersing ground cement particles to avoid agglomerates, enabling an increase in production of up to 25 per cent. 1 In vertical roller mills, they can additionally be used to reduce vibrations and the amount of water

Cement Grinding Aid quot;InCemquot; InCem #174; is the best solution for cement grinding Cement manufacturers have to solve various problems during the production process such as reduction of energy consumption, increase of mill capacity, stabilization of equipment operating modes and improving of the cement quality, Fosroc Cement Additiv, Cement . Get Price

Grinding aids and strength enhancers are well known for their ability to increase cement mill productivity, and the mechanical strength of mortar and concrete. However, little information is available on the potential drawbacks of their usage. To close the gap Sika Services addresses the possible impacts on health and safety and the environment

#0183;#32;The grinding process impacts the cement manufacture in at least two ways. First, an increase of the fineness and homogeneity of the raw mix accelerates the clinkering reactions, leading to less variability of the clinker due to the enhanced stability of the kiln and better energy efficiency in producing a clinker of better consistency.

The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 C.

cement industry and associated emissions and health impacts. Keywords: Cement manufacturing, emissions, SO 2, NO x, PMs, CO 2, environmental impact, health impacts, sustainability. 1. Introduction It is impossible to envisage a modern life without cement. Cement is

The whole process of cement manufacturing in Messebo Cement plant which consists of 7. Cement grinding and storage 8. Cement packing and Dispatch . Figure 1: Process and Quality Flow Diagram to test and control the physical properties of cement fineness during finish milling.

Jan 01, 2014#0183;#32;As a suitable tool for assessing environmental impacts, LCA has been successfully applied to the cement manufacturing and the clinker production and its associated supply chains [8], including direct impacts from the production site as well as indirect impacts, from resources mining and electricity production [8, 9, 10] .

For cement, a cradle to grave assessment is especially difficult because cement has so many end uses, and each use has a unique, often complex lifecycle [6]. Therefore inventory analyses and complete LCAs can be quite complicated [1]. This paper presents the review of the main environmental impacts related to the cement production

Bamburi Cement Ltd Proposed NGP Capacity Increase Project EIA Study Report 2016 ii Report Title: Environment Impact Assessment (EIA) Study Report for Bamburi Cement Nairobi Grinding Plant (NGP) Capacity Increase Project. Firm of Experts: Purified Consultants Ltd (Reg. 2866) P. O. Box 106 00204 AthiRiver, KENYA

WhatsApp)

WhatsApp)