The Basics of How Ore Processing and Recovery Plants

Ore Processing amp; Recovery Plant, Savona Equipment. The Basics of How Ore Processing and Recovery Plants Work. The term processing and recovery plant is broad to say the least so we are going to

WhatsApp)

WhatsApp)

Ore Processing amp; Recovery Plant, Savona Equipment. The Basics of How Ore Processing and Recovery Plants Work. The term processing and recovery plant is broad to say the least so we are going to

The process of panning and sifting for gold uses both of invented in 1874. Other equipment used historically includes the hutch, a trough used with some oredressing machines and the keeve or kiekkkve, a large tub The water extracted from the ore by dewatering is recirculated for plant operations after being sent to a

Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit

offers 1,471 gold ore dressing plant products. About 25% of these are Mineral Separator. A wide variety of gold ore dressing plant options are available to you, such as condition, local service location, and applicable industries.

PbZn ore divides into sulfide PbZn ore and oxide PbZn ore . Flotation is the most widely used in separating sulfide PbZn ore, to separate zinc and plumbum, sometimes for separating sulfide iron and other minerals . Sulfide PbZn ore process divides into priority flotation process, mixseparating flotation, asynchronous flotation,and so on .It is a high technological enterprise that

Online vertaalwoordenboek. NL:ore dressing plant. is een onafhankelijk priv#233;initiatief, gestart in 2004.

Gold mineral flotation normally adopts one stage grindingflotation process, but stages grinding and flotation for ore with uneven distribution. Grinding fineness of gold. For the gold wrapped in sulfide minerals, sulfide ore reaches monomer dissociation; but for the gold with gangue, grinding fineness should reach gold monomer dissociation.

When using environmental gold dressing agent for gold ore leaching, it must first pass the grinding fineness test, pretreatment agent selection test, protection of alkali lime dosage test, environmental gold dressing agent dosage test, leaching time test, slurry concentration test, activated carbon pretreatment test, bottom carbon density test, carbon adsorption time test and carbon leaching

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

Ore Dressing, Ore Dressing Line, Magnetic Separator manufacturer / supplier in China, offering Best Price Gold Ore Separator for Gold Ore Dressing Plant, Limestone Jaw Crusher with Capacity 200tph, 500tpd Cement Making Machine for Sale and so on.

CNFREE Ecofriendly gold leaching chemical is socalled nontoxic and cyanidefree gold dressing agent, LTD. is a hightech enterprise specializing in services including environmentallyfriendly gold ore refining, Cyanide Tailings Discharge Standards in Gold Cyanidation Plants. September,04,2020

gold ore dressing plant Application. There are several different machines could use in gold ore dressing plant, shaking table,spiral chute, gold concentrator, gold trommel, flotation machine. Generally all of these machines are working base on the theoretical of gravity separation, except the flotation machine. chat online leave a message PDF

Define ore dressing. ore dressing synonyms, Ore Dressing Plant Transformation Project of Dayingezhuang Gold Mine, Smelting Plant Transformation Project of Xinhui Copper, and Ore Dressing Process Transformation Project of Sanfengshan Gold Mine have been completed smoothly and put into trial production in advance.

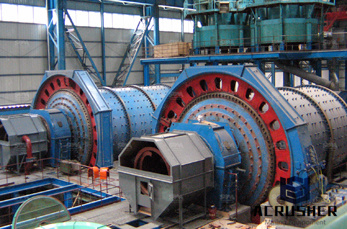

ore dressing plant used table concentrator for gold. ore dressing plant used table concentrator for gold Mineral processing 2019 9 30 The primarily used equipment in crushing are jaw crushers gyratory crushers and cone crushers whereas rod mills and ball mills closed circuited with a classifier unit are generally employed for grinding purposes in a mineral processing plant.

We are offering gold ore concentration plant, mobile gold ore crusher. Gold ore dressing production line gold ore dressing production line are mainly made of jaw crusher, ball mill, classifier, magnetic separator, flotation machine, thickener, dryer and so on .

Get this from a library! Practice of ore dressing of nonferrous, rare and precious metals in the plants of the USSR = (Praktika obogashcheniya rud tsvetnykh, redkikh i blagorodnykh metallov na fabrikakh SSSR). [United States. Bureau of Mines.; National Science Foundation ();]

10 Steps For Gold Leaching Using Environmental Gold Dressing Agent. May,24,2019 Flotation Conditioners of Oxidized Zinc and Lead Ore. May,15,2019 The Introduction of Flotation Frothers. May,08,2019 Gold Leaching Reagent Compared to Cyanide in Gold Mining Plant. April,24,2019

WhatsApp)

WhatsApp)