(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the

WhatsApp)

WhatsApp)

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the

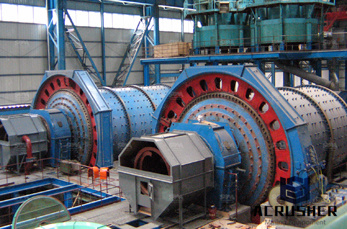

Base Metals Project. South America Complete Comminution circuit designed and supplied to Base Metals mine in South America, including Complete C140 Primary Crushing Station, Conveyors, LoadOut Station, 3MW SAG Mill, Ball Mill, Ball Loading Station amp; Scats Crushing Circuit.

Mill head design causing excessive downtime . The Masbate Gold Projects operations are comprised of a large conventional openpit mine feeding ore to a process plant consisting of crushing, grinding and a carboninleach (CIL) process step. Crushing is performed in a single stage using a jaw crusher.

Mining Ore World Ball Mill Planet Gold Ores. Nakayama Ball Mill World Gold Ores. Pumping up gold production rates at greenfields mill pumping up gold production rates at greenfields mill Sep 20 2019 the plant has a unique setup with three ball mills allowing the circuit to be optimised for gold recovery depending on the needs of different clients in its current configuration the plant can

MM 200, 301 mixer mill, S 100 centrifugal ball mill and PM 400 planetary ball mill (1) MM 400 mixer mill (2) MicroMill grinder (1) Mid size grinding vial set (2) Mid size, CrFree, Polyvial grinding vial set (1) Mortar grinder RM 200 (1) PM 100 and PM 200 planetary ball mill (2) RM 100 mortar grinder (1) SamplePrep grinding vial, vial set (1)

operating parameters. Mill speed, mill charge, ball size, and wet grinding are the parameters which have been selected for the present study. It is hoped that the analysis of the data acquired will allow insight as to which parameters will require a functional form if they were to be integrated into a complete liberation model. #183;

Ball mill design is rather simple. This grinding equipment is a drum filled with metal or cast iron balls (grinding media). It is used mostly for production of bulk construction materials, paints, pyrotechnical devices, ceramics and in other industries. The ball mill patent was sealed more than 180 years ago.

30/5/2016#0183;#32;This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder. Ball mill is a cylindrical device that used to grind and blend raw

Wiki says quot;A ball mill is a type of grinder used to grind materials into extremely fine powder for use in paints, pyrotechnics, and ceramics.quot; Many instructables refer to United Nuclear Ball Mills. Their small ball mill cost between 70 and 80 dollars. For no more than 30 and in 5 minute you can build a ball mill of appreciable performance.

17/9/2020#0183;#32;The Bond Ball Mill Work Index remains today as the only tool used for ball mill scaleup design. For an (only nominally, not at all materially modified) update on its use for industrial mill sizing, see Selection of Rod Mills, Ball Mills, Pebble Mills, and Regrind Mills, Rowland, C. A., Jr., 1982, Chapter 23, Design and Installation of Comminution Circuits, SME of AIME.

Rocking shaker is a longtime seller product proud of the more than 2000 results for 30 years since containers can be set, and it disperses strong by a short time by threedimensional compound can also be inverter allows you to adjust the of the mechanical design, electrical design,assembly, and inspection are performed at our own

There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial set of liners is rarely the final design selected. Based upon individual experience, mill superintendents develop preferences for liner designs. The following is given as a guideline for the initial set

Oct 30, 2020#0183;#32;The Otjikoto Gold Mine in the Republic of Namibia is located approximately 300 kilometers north of the capital city of Windhoek. The project features surface mining with a modern gravity/carboninpulp mill for ore treatment and recovery of gold. Initial mill design capacity was million tonne per annum but then expanded after 9 months of operation to million tonne per annum.

Dec 01, 2013#0183;#32;1. Introduction. Wet ball mill is one of the most predominantly used method for the purpose of mixing and grinding of raw materials in laboratories and industry,, .The ball mill process is very complicated process governed by many parameters, such as ball size, ball shape, ball filling, slurry loading (with respect to ball amount), powder loading with respect to the amount of total slurry

Optimization of mill performance by using online ball and pulp measurements by B. Clermont* and B. de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator. Comminution is responsible for 50% of the total mineral processing cost. In todays global markets, expanding mining groups are trying

copper cone grinding ball mill in india. Founded in 1997, Shandong Xinhai Mining Technology amp; Equipment Inc, (Stock Code: 836079) under Xinhai is a stockholding high and new technology enterprise to provide the Turnkey Solution for Mineral Processing Plant; including design and research, machine manufacturing, equipment procurement, management service, mine operation, mine materials

Abstract: Processing in planetary ball mills is well suited to a large number of applications because they are easy to operate and versatile, grinding faster than other mills. Research related to planetary mills are mainly about the process evaluation, and there are few studies on the mechanical design

Ball mills (Fig. ) are short cylindrical vessels with a shell to diameter ratio of to 1 and less. When the length to diameter ratio varies between 3 and 5 it is called tube mill. The grinding medium is highcarbon or cast alloy steel balls. The particle size of the feed usually does not exceed 2025 mm.

Sep 17, 2020#0183;#32;The Bond Ball Mill Work Index remains today as the only tool used for ball mill scaleup design. For an (only nominally, not at all materially modified) update on its use for industrial mill sizing, see Selection of Rod Mills, Ball Mills, Pebble Mills, and Regrind Mills, Rowland, C. A., Jr., 1982, Chapter 23, Design and Installation of

A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to

Outotec#174; MH Series Grinding Mills offer a cost effective, and easy to operate and maintain grinding solution across the mill lifecycle. The MH Series includes a range of SAG, ball, and rod mills in standardized sizes with a capacity of up to MW installed power, and is based on over 100 years of experience with grinding technologies.

concrete ball mills for salemade in usa; mills golf victor ny; grinding machine micron; grinder recycled plastic bottle crusher; grinding mill zimbabwe; design plans for ball mill grinder; four cylinder rodball mill; mill mainly for gold; limeore wet ball mill germany; hammer mill vs ring granulator for coal

Process And Design Of Ball Mill. Process And Design Of Ball Mill. Fundamentals of mechanical alloying processes in ball mills. A ball mill is a relatively simple apparatus in which the motion of the reactor, or of a part of it, induces a series of collisions of balls with each other and with the reactor walls (Suryanarayana, 2001).

Grinding Mills: Ball Mill amp; Rod Mill Design amp; Parts. Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their

WhatsApp)

WhatsApp)