Calcium Carbide Meters | Reagents | Ampules

A selection of Calcium carbide meters, reagents and ampules for checking moisture measurements.

WhatsApp)

WhatsApp)

A selection of Calcium carbide meters, reagents and ampules for checking moisture measurements.

Project Report on Pvc Resin From Calcium Carbide Project Report on Pvc Resin From Calcium Carbide includes Present Market Position and Expected Future Demand, Technology, Manufacturing Process, Investment Opportunity, Plant Economics and Project Financials. Report provides a comprehensive analysis from industry covering detailed reporting and evaluates the position of the

Calcium carbide and carbon monoxide are produced in this step. Preparation of acetylene from calcium carbide Calcium carbide and water reaction | CaC 2 + H 2 O = HCCH + Ca(OH) 2. Add calcium carbide into water. You can see a smoke is coming out of water. This smoke is the acetylene gas which is highly flammable. Acetylene''s IUPAC name is ethyne.

CaO + 3 C CaC 2 + CO. The high temperature required for this reaction is not practically achievable by traditional combustion, so the reaction is performed in an electric arc furnace with graphite electrodes. The carbide product produced generally contains around 80% calcium carbide by weight.

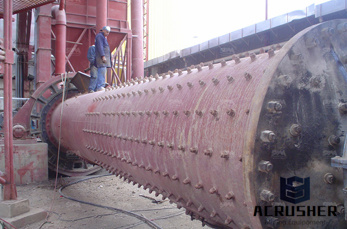

The calcium carbide slag is fed into the dryer through the belt conveyor and Fu zipper machine from the reservoir, mixed with the hot air from the end of the kiln of the humidifying tower and dried in the dryer.

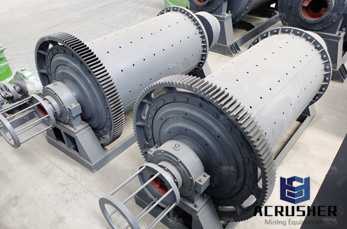

Calcium Carbide Production Machinery Teddy Bear Gift. Calcium Carbide Production Machinery. Jaw Crusher. Jaw crusher is firstly researched and developed in 1858. Due

XSM is a leading global manufacturer of crushing and milling equipment,XSM also supply individual (calcium carbide plant and machinery...) crushers and mills as well as spare parts of them. XSM offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan.

Feb 14, 2016 calcium carbide manufacturing plant for sale and carbon calcium carbide plant and machinery chile Calcium Carbide Slag in Inner Mongolia, Properties of Chemically Combusted Calcium Carbide Residue and Feb 13, 2015 Calcium carbide residue (CCR) is a waste byproduct from acetylene gas At present, the construction industry is.

Introduction to Acetylene Generation Process Using Calcium Carbide. In various industrial environments, acetylene generation is initiated in acetylene producing generators. These equipment are sold in various capacities from 8 m 3 to over 200 m 3 per hour. Calcium carbide is introduced from the top of the generator shell into the water.

Calcium Carbide for Acetylene Production Acetylene is a combustible gas with a distinctive odor. It is used as a raw material for the production of several organic chemicals, as well as a fuel component in metal cutting, and oxyacetylene welding.

Calcium carbide also known as CaC is mainly used in the production of acetylene, calcium cyanamide, toy cannons, carbide lamps, and other organic chemicals. It is also used for desulfurization, slag conditioning, and furnace injection applications during steel production. In the current scenario, it is majorly used in the production of acetylene gas which is further used for the production of polyvinyl

Commercial calcium carbide varies in colour from Steelgrey to reddish brown, depending on impurities and the method of manufacture. It is made from lime and coke in the electric furnace at temperature of 2200 2500oC, using large amount of electric power. Industrial calcium carbide is about 80% pure remaining is calcium oxide and 25% other

50/80mm Machinery Calcium Carbide For Sale, Find Complete Details about 50/80mm Machinery Calcium Carbide For Sale,Calcium Carbide For Sale,Calcium Carbide 50/80mm,Calcium Carbide Machinery from Other Inorganic Salts Supplier or ManufacturerFortis (Tianjin) International Trade Co.,

Dec 11, 2016#0183;#32;Shanghai CME (Calcium Carbide Manufacturing Plant) is professional manufacturer, the main production stone crusher carbide manufacture machine calcium carbide production machinery...

calcium carbide plant and machinery chile AP42 CH 114 Calcium Carbide Manufacturing US The process for manufacturing calcium carbide is illustrated in Figure 1141 arc furnace the primary piece of equipment used to produce calcium carbide Read More History. calcium carbide plant

A wide variety of calcium carbide machinery options are available to you, such as none, egypt, and united states. You can also choose from easy to operate, automatic, and long service life. As well as from pipe, film, and granules. And whether calcium carbide machinery

calcium carbide manufacturer/supplier, China calcium carbide manufacturer amp; factory list, find qualified Chinese calcium carbide manufacturers, suppliers, factories, exporters amp; wholesalers quickly on, page 2. Industrial Quicklime Production Plant Machinery.

Calcium Carbide Manufacturing General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100#176;C (3632 to 3812#176;F) in an electric arc furnace. At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3CCaC2+CO Lime for the reaction is usually made by calcining

This publication has collected information from calcium carbide manufacturers, withdrawn national standards and gas companies experience in order to establish an updated and current standard for calcium carbide to be used for the production of acetylene. 2 Scope and purpose Scope Calcium carbide intended for the production of acetylene.

Acetylene is generated as a result of the chemical reaction between calcium carbide and water. The generator is designed to generate acetylene at a pressure of 7 psi. Acetylene Generator CE quality acetylene world class generator with twin carbide charging. CONDENSER : The condensor cools and purifies the gas thereby condensing the excessive moisture. Cooling water is circulated on the shell

calcium carbide equipment, power plant, calcium carbide stone, chinese calcium carbide grinding plants. planetary and vibratory micro mill wikipedia. ball mill 8 Mining Machinery set up of calciam carbonate grinding mill

Calcium carbide (CaC 2) is manufactured by heating a lime and carbon mixture to 2000 E to 2100 EC (3632 E to 3812 EF) in an electric arc furnace. At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO + 3C 6 CaC 2 + CO

Calcium carbide became one of the most important chemicals of the 20th century. We are leading company in this field, We provide is specific solutions for our every customers. We have been soaring heights of success by offering superior quality products to the clients across the globe.

WhatsApp)

WhatsApp)