Sponge Iron Limestone

Limestone Used In Production Of Sponge Iron. Iron Making. pellets are the feed for sponge iron production. The blast . value since it contains lot of CO; the gas is

WhatsApp)

WhatsApp)

Limestone Used In Production Of Sponge Iron. Iron Making. pellets are the feed for sponge iron production. The blast . value since it contains lot of CO; the gas is

sponge iron production in rotary kiln. Sponge iron production in rotary kiln the major raw materials required for production of sponge iron by the rotary kiln process are sized graded iron ore and noncoking coal limestone in small quantities is also required to scavenge the sulphur iron ore the quality requirement of sized ore for sponge iron production we are a professional mining machinery manufacturer, the main

Limestone is used mainly in the iron, The production of iron or steel is a process, Open hearth steelmaking means the pig iron, more iron ore and limestone [Chat Online] Limestone Used In Production Of Sponge Iron The process of manufacturing sponge iron or DRI is known as DR process Liquid hot metal and solid pig iron would also be .

Sponge Iron vs Pig Iron Pig iron and sponge iron are two different iron forms that are a result of different production processes. Sponge iron can be produced by direct reduction of iron ore through reducing agents whereas pig iron is produced by melting iron ore with charcoal and limestone at

limestone used in production of sponge iron advantages of limestone in sponge iron process. advantages of liTONne in sponge iron process The Bessemer process was the first inexpensive industrial process for the mass production of steel from molten pig iron before the development of the open hearth furnaceThe key principle is removal of impurities from the iron by oxidation with air

7/7/2017#0183;#32;Limestone is also one of the vital raw materials used in production of iron and steel. Limestone, by definition, is a rock that contains at least 50 % of CaCO3 in the form of calcite by weight. There can be small particles of quartz (silica), feldspar (aluminosilicates), clay minerals, pyrite (iron sulphide), siderite (iron carbonate), and other minerals associated with the limestone.

Sponge iron production in rotary kiln pdfBangla islamic dua book pdf PDF The present paper deals with 2D CFD model of sponge iron rotary kilns. Using this model In the sponge iron industry rotary kiln is the primary equip. ment which is fects the production capacities of these industries.

Apr 30 2011 #183; Sponge Iron vs Pig Iron Sponge iron can be produced by direct reduction of iron ore through reducing agents whereas pig iron is produced by melting iron ore with charcoal and limestone at very high pressures Pig iron is soft and brittle because of high carbon content but is used to make wrought iron and steel that are extremely useful

The major Raw Materials required for production of Sponge Iron by the rotary kiln process are: sized graded Iron Ore and NonCoking coal. Limestone, in small quantities, is also required to scavenge the sulphur. IRON ORE The quality requirement of Sized ore for sponge iron production

The major Raw Materials required for production of Sponge Iron by the rotary kiln process are: sized graded Iron Ore and NonCoking coal. Limestone, in small quantities, is also required to scavenge the sulphur. IRON ORE The quality requirement of Sized ore for sponge iron production can be classified into: spongeitc 2 1) Physical requirements: Strength and granulometry are the two

DOLOMITE/LIMESTONE Limestone is used as a desulphuriser in the production of sponge iron. Typical specification of limestone is given below CHEMICAL COMPOSITION PERCENTAGE MIX MgO 22% (Minimum) CaO 28% (Maximum)

limestone required to make sponge iron May 08 2013 #183; Specification of limestone and dolomite for iron making is less rigid But for steelmaking limestone need to have very low SiO2 and Al2O3 since these elements require additional flux to neutralize them which increases the slag volumes Further additional heat is required for keeping fluid this amount of additional slag

Limestone In Pig Iron Process. Limestone Used In Production Of Sponge Iron The process of manufacturing sponge iron or DRI is known as DR process Liquid hot metal and solid pig iron would also be . Read the rest gt; Direct Reduction Iron Production Plant Iron Ore Rotary

is limestone used in the production of sponge iron primus process for sponge iron production. The direct reduction process generates metallic iron in the solid form i e sponge iron or DRI which is used chiefly for the EAF steel production The smelting reduction process serves to produce of the hot metal These proces ses are highly important to the EAF get price

Limestone Its Processing and Application in Iron and Steel Industry

A blast furnace is used to turn iron ore into pig iron, an intermediate material used in the production of iron and steel. Figure 5 illustrates that this industry usesIt''s the addition of limestone to the blast furnace along with the heat from the coke and breeze that turns the wrought iron into pig iron.

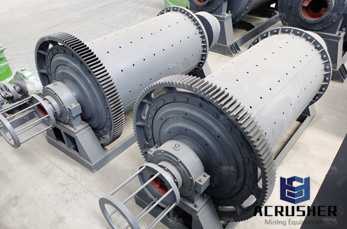

germany used crucher equipment. How Is Bauxite Formed ReferenceMar 26, 2020#183; Latertitic bauxite ores are largely formed in tropical regions by the weathering o. shale raymond mill type and ac motor motor type raymond mill

Sponge iron is a product produced using iron ore that''s often used for making wrought iron and the gases processing for iron production India. Process for

WhatsApp)

WhatsApp)