Ball Mill, Grinding Mill, Ball Mill Manufacturers, Ball

Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energysaving ball mill up to 30%, great ball mill working principle, which greatly reduces the

WhatsApp)

WhatsApp)

Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energysaving ball mill up to 30%, great ball mill working principle, which greatly reduces the

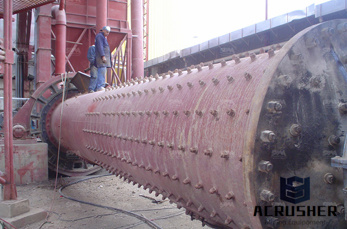

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Gold Ore Ball Mill for Grinding Stone Gold ore ball mill for grinding stone Ball mill is the key recrush eqipment after the crushing. Ball mill is widely used in cement, silicate products, new building materials, refractories, chemical fertilizer, black and nonferrous metal oredressing, as well as the production industry of glass or ceramics, for carry though dry or wet grinding of a

Feldspar and Quartz Sand Grinding Equipment of Rod Ball Mill FOB Price: US 3,00050,000 / Piece. Min. Order: 1 Piece Contact Now. Dry Process Cement Production Rotary Kiln FOB Price: US 350,000500,000 / Piece. Min. Order: 1 Piece

News Fine Impact Mill ~Condux 60 Smallest, complete Grinding Plant NETZSCH intensifies Activities in the Minerals Sector with the Acquisition of Ecutec The Best of Both Worlds SMARTREMOVAL has revolutionized filter hose changing Dry Finest Grinding into the Submicron Range

The energy efficiency of dry fine grinding process of powders dramatically declines with decreasing particle size, and represents a growing concern in various cuttingedge technical applications for pharmaceutical and cosmetic products, advancedceramics, and food industry. In this paper, we report on a detailed experimental analysis of the longterm grinding behavior of silica sand as a model

Silica Sand Mill Ball Mill For Grinding Silica SandBuy The ball mill is a key equipment to grind the crushed materials and the ball mill is widely used in powdermaking production line including cement silicate newtype building material refractory material fertilizer ore dressing of ferrous metal and nonferrous metal glass ceramics etc and the ball mill can grind various ores and other

Enterprise strength is an important factor in inspecting manufacturers. heavy industry technology, as a strong supplier of grinding equipment, has continuously explored the market of industrial milling projects with 30 years of market experience.

Grinding Dry Sand Ball Mill. Ball mill is an efficient tool for fine powder grindinghe ball mill is used to grind many kinds of mine and other materials, or to select the mineall mill is widely used in building material, chemical industry, etc there are two ways of grinding the dry way and the wet wayt can be divided into tabular type and.

Basic Ball Mill Grinding Circuit. Cleaning and Storing of Ball Mill Charge after the Bond Work Index Procedure is done Add about 500 g of silica sand into the mill containing the ball charge Seal the mill Rotate for 20 revolutions to clean Empty the mill charge and sand into the ball try once grinding is complete Clean out the mill using a brush Put the lid on the mill

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

The ball mill liner is used to protect the cylinder body from direct impact and friction of the grinding body and the material. At the same time, different forms of mill liner can be used to adjust the movement state of the grinding body to enhance the grinding effect of the grinding body on the material, Help to improve the grinding efficiency of the mill, increase production and reduce metal

Energy saving Ball Mill Promotes the Development of Grinding Industry. The new building materials, refractory materials, chemical fertilizer, black and nonferrous metal processing and glass ceramics industry production can use energysaving ball mill to realize dry or wet grinding. Details

offers 2,902 ball mill grinding sand products. About 1% of these are other toys amp; hobbies. A wide variety of ball mill grinding sand options are available to

#0183;#32;This video is unavailable. Watch Queue Queue. Watch Queue Queue

Grinding Solutions offers a range of Bond Work Index Testing from crushability and abrasion to ball and rod mills. For more information on the tests please see below: Bond Low Energy Impact Test. The Bond LowEnergy Impact test can be used to determine the Crusher Work index (CWi), also known as the Impact Work Index.

Grinding in small plants, as in larger installations, has proven to be the most costly of all unit operations from both capital and operating standpoints. Therefore, grinding deserves the most scrutiny of all operations during the design procedure. A recent survey by a major grinding mill manufacturer reveals that more than 80 autogenous or semiautogenous mills having between 100 and 1,000

offers 189 ball mill for grinding silica sand products. About 29% of these are Mine Mill. A wide variety of ball mill for grinding silica sand options are available to you, such as condition, local service location, and applicable industries.

#0183;#32;With the use of latest in equipment and quality material, we have been successful in offering Vertical Sand Mill. this machine Used mainly in paint, ink amp; co...

WhatsApp)

WhatsApp)