Vertical Roller Mill Components Panzercrom

Components VERTICAL ROLLER MILL COMPONENTS. BACK. Corporate

WhatsApp)

WhatsApp)

Components VERTICAL ROLLER MILL COMPONENTS. BACK. Corporate

The vertical roller mill has the advantages of high grinding efficiency, low power consumption and high automation. It has been widely used in cement production. The grinding roller is the main grinding component of the vertical roller mill.

Vertical Roller Mills FL

The Vertical Roller Mill Components. 10/12/2014 0 Comments While in the electricity, coal, constructing resources and also the metallurgical marketplace, vertical roller mill has a wide application and is the important thing products inside the powder production line.

vertical roller mill hydraulic system: component used for applying sufficient pressure to the grinding roller to crush materials. Controlled System Pressure applied to the grinding roller being automatically controlled by the PLC/dCs enables the accurate control of grinding pressure and the highly efficient and stable operation of the mill without manual operation.

As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to. maximise productivity and minimise operating costs. The high energy efficiency is especially beneficial in regions with limited power generating capacity or where electricity availability is limited.

Raymond#174; Roller Mills Deliver Maximum Productivity Mill and all relating components are then thoroughly cleaned, sandblasted, primed, painted,, and properly in the vertical mill include GRAPHITE, TALC, COCOA, LIMESTONE, KAOLIN, PHARMACEUTICALS, and

Vertical Roller Mill Parts ecorporatesVertical Roller Mill Parts Ecorporates is leading and experienced supplier of highquality wear resistant parts for Ve vertical roller mill

Vertical roller mills VAUTID INDIA Private Ltd. VAUTID has a comprehensive portfolio of wear resistance solutions for vertical mills. As well as offering new components and replacement parts produced from composite wear plates and castings, VAUTID can also rework your wornout components.

Vertical roller mill is mainly used for grinding raw meal, clinker, GGBFS (Ground Granulated Blast Furnace Slag), iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz, clay, sandstone,

India: Shree Cement has ordered two vertical roller (VR) mills from Germanybased Gebr. Pfeiffer for the upcoming clinker line at its Raipur cement plant in Chhattisgarh. The supplier says that one of the mills will grind raw materials and the other will grind coal.

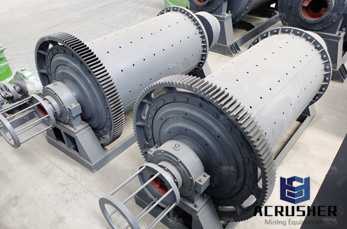

Vertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. According to MIIT, grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill.

#0183;#32;Belgium: Magotteaux has launched Expand, a vertical roller mill (WRM) wear parts product line for the cement industry. The equipment supplier says that the range offers high resistance, consistent production, energy efficiency and lower maintenance and replacement frequency.

Vertical Roller Mill Safety Review of basic components 1. Isolate the Mill from the System 2. Lock out the Mill and Auxiliaries LOTOTO Grinding Components Separator Dust collector fan Mill isolation dampers (closed) Hot gas generators Mill feed system Material recirculation

WhatsApp)

WhatsApp)