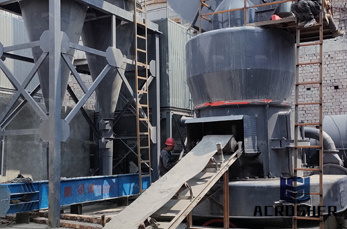

Micronizing plant manufacturer, Mineral Grinding Plant

We have supplied plants of upto TPH mineral throughput of D97 10 micron material. Whether the need is for dry grinding or wet grinding, we will have the process laid out to

WhatsApp)

WhatsApp)

We have supplied plants of upto TPH mineral throughput of D97 10 micron material. Whether the need is for dry grinding or wet grinding, we will have the process laid out to

Home; Products; manufacturing process of a chrome grinding ball mill plant; manufacturing process of a chrome grinding ball mill plant

Mineral Grinding Process Detail ristoranteilbettolino. mineral grinding process detail . AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding

Process Minerals, Inc. was established in 1981. We are an industry leader in additives and fillers through a world class manufacturing process. Our products, C1 Cristobalite and CristolBrite are key ingredients in thousands of products worldwide.

fine grinding of industrial minerals. Nov 12 2008 Fine grinding is a process stage that is necessary for all industrial minerals some of which have to be ground to the submicron range The following contribution provides an overview of the important industrial minerals their manufacturing processes the fineness requirements and the processes employed for dry and wet grinding .

Grinding minerals can be hard on even the most durable equipment. MPE mineral particle size reduction equipment uses worldclass drive components, rolllife enhancing technologies, and yield unmatchable accuracy. We grind everything from barite to talc powder.

process to make mineral powder Grinding Mill China. Process of Grinding a Mineral Into a Fine Powder | With so many cosmetic powders on the market, choosing the right one for you can seem like a daunting task.

Ball mill is a common grinding equipment in concentrator, the main role is to provide qualified grinding products for the subsequent dressing process. The Guide of Grinding Equipment Grinding equipment is one of the important equipment used before mineral processing operation.

Dewatering is an important process in mineral processing. The purpose of dewatering is to remove water absorbed by the particles which increases the pulp density. This is done for a number of reasons, specifically, to enable ore handling and concentrates to be transported easily, allow further processing to occur and to dispose of the gangue.

#0183;#32;The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a process of ore preparation, milling, and ore dressing

Mineral Grinding Process Detail ristoranteilbettolino. mineral grinding process detail . AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding

Industrial Mineral Processing. While their importance is paramount to the production process, in the end, the production of these raw materials operates on a very tight profit margin. Thats why efficiency and quality of mineral grinding has become an important part of process controls.

Product Manufacturing Pro Cess In Mineral Grinding Plants . Product manufacturing pro cess in mineral grinding plants process control for cement grinding in arpn he power ingesting of a grinding process is 5060 in the cement production power consumptionhe vertical roller mill vrm reduces the power consumption for cement grinding approximately

mineral grinding optimality range characterized by the maximum dissociation of minerals and by the minimized transition of valuable components in slurry that is difficult to pro cess. These issues are of the high concern in studying grindability and dissociation ability of complex ores that, aside from the

grinding process minerals wet grinding and dry grinding; both open circuit grinding and closed circuit grinding For ores and minerals grinding, there are ball mill . Blog of Mineral Processing (Metallurgy) Articles. Mineral Processing amp; Extractive Metallurgy explained in simple practical terms engineers and operators can understand.

Product Manufacturing Pro Cess In Mineral Grinding Plants. Process control for cement grinding in arpn he power ingesting of a grinding process is 5060 in the cement production power consumptionhe vertical roller mill vrm reduces the power consumption for cement grinding approximately 3040 associated with other grinding millshe process variables in cement grinding process using.

process mineral grinding. In the previous chapter, the various laws of comminution which have been propounded have been studied in relation to the physical process of size reduction and to the available results of experiments into the fracture of homogeneous and heterogeneous materials by impact and by slow compression in this study it is seen that no satisfactory law of comminution has yet

Mineral grinding process general includes three stages, the raw mineral crushing process, mineral mill process and final mineral powder collecting process. 1. Why we need to crush raw material. According to our statistics, 90% customers raw materials are bigger than the max. feeding size of grinding

Grinding Process In Iron Ore antwerpsehavenpijl . Grinding Process In Iron Ore. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Mar 14, 2014#0183;#32;Grinding is a subset of cutting, as grinding is a true metalcutting process. Grinding is very common in mineral processing plants and the cement industry. Grinding is used to finish workpieces that must show high surface quality and high accuracy of shape and dimension.

Mineral processing typically involves the crushing and grinding of hard rock ore. Crushed ore is introduced to semiautogenous grinding (SAG) mills, also known as primary mills, where grinding media is released like hammers to assist in the ore cracking / grinding process.

WhatsApp)

WhatsApp)