(PDF) Grinding in Ball Mills: Modeling and Process Control

precise and complicated mathematical models of the grinding process including . approach is most frequently used in ball mill grinding circuits. The main advantage .

WhatsApp)

WhatsApp)

precise and complicated mathematical models of the grinding process including . approach is most frequently used in ball mill grinding circuits. The main advantage .

Several factors affect the efficiency of a ball mill for cement grinding. In this article, we shall be looking at some of these factors that have been proven to influence grinding efficiency: Mill Geometry And Speed. According to Bond (1954), the grinding efficiency of a mill depends on the ball mill diameter, size of the media and mill speed.

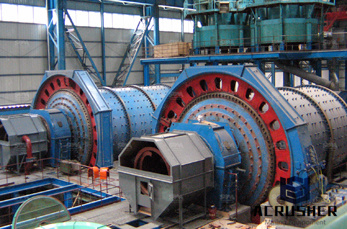

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Ball mills grind material by impact and attrition. The degree of milling in a ball mill is influenced by; a. Residence time of the material in the mill chamber. b. The size, density, and number of the balls. c. The nature of the balls (hardness of the grinding material)

Ball mill is a cylindrical device that used to grind and blend raw materials and it rotates around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

how to make a ball grinding mill how to build a ball mill for grinding Ball mill, Grinding machine, Wet ball mill, Dry ball mill, Milling machine, Duration: 3:57. Quick and Easy Black Powder Ball Mill Skylighter Take just 20 minutes to read this article, print it out, and use it to make

On the basis of historical data, Dry Grinding Ball Mill market report provides key segments and their subsegments, revenue and demand amp; supply data. Considering technological breakthroughs of the market Dry Grinding Ball Mill industry is likely to appear as a commendable platform for emerging Dry Grinding Ball Mill market investors.

Compare Impact Grinding Ball Mill And Ball Mill. Ika introduces the worlds first disposable grinding system for safe, instant and precise milling resultsts unique and compact design makes the unit space saving and ultraportablehe disposable grinding chamber eliminates the possibility of crosscontamination and saves you cleaning costs and timeonvenient and safe to use while assuring high

Ball Mills. Ball mills are industrial crushing tools that are characterized by their use of loose crushing media. Ball mills are just one of many size reduction equipment varieties. Ball mills, along with grinding mills, impact crushers and a variety of other equipment, are used for the reduction of all kinds of materials for all kinds of purposes.

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

how to make ball mill grinding media. Dec, this would involve the media top selection size and the graded ball recharging as well the principle applied here is that larger balls are suitable for coarse grinding while smaller balls are suited for fine grinding this same principle is applied in ball mill cement grinding either with the use of division head, classifying liners or ox

principles of grinding in ball mill . Modification And Change In Ball Mill. China Supplier of Methods of Modification And Change In Ball MillTrade show has always been a barometer of market development, it is learned, Methods of Modific. Mining Equipment For Ore Surface Processing.

Nova S ball mill is the preferred solution for finegrinding of various masses like compounds, spreads, creams for fillings and coatings, cocoa masses, nut pastes and other fatbased masses. The unique grinding chamber delivers onestepgrinding at low temperatures, ensuring that your product has the highest and consistent quality.

This test also shows that by feeding the mill with a too dilute pulp, the grinding zones between the media are not saturated, leading to high media wear rate. A variation in total ball angle can be detected and linked to grinding efficiency and charge expansion. This could help the operator to make the right decision and keep the mill

Automation Makes Precise Grinding In Indonesia; Automation Makes Precise Grinding In Indonesia. Processing ability:2120t/h. Feeding size: 1530mm. Product granularity: 1530mm. High pressure grinding mill can grind stone into powder that commonly used in chemical plant or a power plant, etc. Get a Quote Send Message.

WhatsApp)

WhatsApp)