Extracting precious zinc from waste ash | EurekAlert

#0183;#32;The method developed at Chalmers does not extract pure zinc metal, but instead a simpler process is used where the end product contains a very high proportion of

WhatsApp)

WhatsApp)

#0183;#32;The method developed at Chalmers does not extract pure zinc metal, but instead a simpler process is used where the end product contains a very high proportion of

The collected fresh fly ash (FA) is mixed with the residues of the wet flue gas treatment (neutral and acidic scrub water) in the FLUWAprocess and extracted in a multistage cascade. The scrub water is used to extract heavy metals such as Zn, Pb, Cd and Cu

The overall goal of this study is to develop a suitable flow sheet to extract rare earth elements (REEs) from coal ash. A total of 14 coal samples of different ranks were examined for REE

Some studies have been undertaken to reduce and extract heavy metals from ash and sand of the boiler using carbon dioxide as its ligand [10], absorption of Cs +, Co 2+, Eu 3+ on zirconium silikat...

#0183;#32;In our previous study ( Hong et al., submitted ), a washing process was performed to extract heavy metals from MSW incinerator fly ash by the treatment with chelating agents such as EDTA and DTPA. In comparison to acid, EDTA and DTPA were effective in detoxifying MSW incinerator fly ash in the wide pH range.

#0183;#32;1. Introduction. Coal fly ash (CFA) is a kind of industrial solid residue, which is derived from the combustion processes in coalfired power plants [].The alumina content in CFA, produced in the southern Inner Mongolia of China, is in the range of 3050% [2,3].The annual production of CFA is estimated to be 580 million tons, which contains approximately 174290 million tons of alumina [].

One possible way to extract metals from the waste products is to use electrochemical methods. In order to implement these techn iques on an industrial scale, there are several parameters that have to be considered. One important parameter is the choice of material of the electrode, which

tons of bottom ash and 60 000 tons of fly ash annually still remain and have to be deposited due to their elevated concentrations of toxic substances. Today, one third of the Swiss MSWI plants are performing an acidic leaching process (FLUWA) to separate heavy metals from the fly ash.

fly ash. These contain relatively high concentrations of heavy metals, which make them harmful to the environment if not taken care of, but also make them valuable resources if the metals could be extracted and reutilized. One possible way to extract metals from the

Stringent leaching conditions including high pressure, temperature, and chemical consumption limit the extraction of valuable metals from circulating fluidized bedderived highalumina fly ash (CFBHAFA) via the acid leaching method. In the present study, a complex utilization of CFBHAFA, including the extraction of valuable metals (Al, Li, and Ga) and preparation of mesoporous material, is

Solid waste incineration produces millions of tons of fly ash that ends up in landfills. But it often contains a large number of valuable metals such as zinc. A new method from scientists at the Chalmers University of Technology will help in extracting them. During waste incineration, flue

Urban mining from fly ash resulting from municipal solid waste incineration (MSWI) is becoming more and more important due to the increasing scarcity of supplycritical metals. Metal extraction from acid fly ash leaching has already been established. In this context selective Cu recovery is still a challenge. Therefore, our purpose was the separation of Cu(II) from MSWI fly ash extracts by

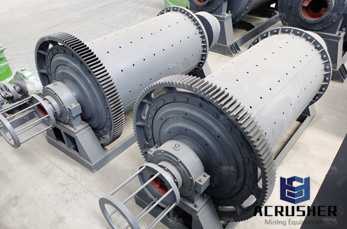

Metal extraction with focus on Zn from fly ash by means of using acid process waters. Every year over 5 000 000 ton of solid waste are combusted in Sweden. In addition to the production of heat and electricity, this also results in large quantities of ash.

#0183;#32;There are currently some established plants for extracting zinc and other substances from fly ash in Europe, and in one plant pure zinc metal is produced in a complex process.

aqueous solgel process which produces agglomerated fly ash particles and extracted chlorides. The thermal tre a t m e n t consists, after drying at 60#176;C, in calcining the fly ash Metal Leaching from MSW Fly Ash Before and After Chemical and Thermal Treatments S. Iretska ya Institute of Technology, SaintPetersbourg, 198013, Russia A. Nzihou

WhatsApp)

WhatsApp)