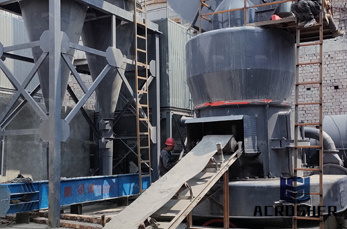

cement plant vertical raw mill maintain stable operation

cement plant vertical raw mill maintain stable operation 5365 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry.

WhatsApp)

WhatsApp)

cement plant vertical raw mill maintain stable operation 5365 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry.

#0183;#32; points Stable Beds: to maintain stability and bed material, which isgrinding roller grinding bed basis, the normal operation of thekey. Material thickness can be adjusted to adjust the height ofretaining ring material, a suitable thickness and theirrelationship with the correspondence between the verticalroller mill output should be in the debugging stage of the firstto

fls atox vertical raw mill operation Grinding theory of vertical roller millGrinding in roller mill is effected Operation points Stable Beds: Cement industry news PPT The OK mill The

FLOur vertical roller mill offers optimum raw . Vertical roller mill with peak raw cement and slag grinding performance Our costsaving Vertical Roller Mill (VRM) exhibits a modern design approach. We continuously improve our solution with the latest updates to enhance . Service Online; how to maintain raw ball mill oreration in cement plant

According to different materials,our company researched and developed five different kinds of PFRM vertical mill,include cement raw vertical is unnecessary for largescale and medium vertical mill. 4. Stable chemical composition and with various machines, such as cement production line, cement grinding plant, active lime

LM Vertical Roller Mill Product features: Integration of multiple functions, more stable and reliable. Feed particle size: 070mm; Production capacity: 3340 tons / hour

Vertical roller mill has the advantages of high grinding efficiency, large output and low energy consumption. capacity range from 5th to 350th. the feeding size is less than or equal to 110mm. vertical raw mill. cost of vertical roller mill in cement processing plant. cement roller mill is an efficient tool for cement fine powder grinding. get

cement mill operations in four ways: More consistent quality (grade). the grinding circuit of a raw mill are an increase in output and a reduction in power consumption. Expert Optimizer has been The grinding plant operation can be coordinated IT optimization. IT.

Operation. Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the

known reputation of the OK mill as a reliable machine that is easy to operate and maintain continues with the OK raw mill. In addition to the roller design features, the OK mill retains the ability to operate with a reduced number of rollers if needed. The highefficiency separator gives a steep separation curve, resulting in stable kiln operation.

The solution was applied first in the raw material millRM3, a vertical roller mill LM with a capacity of 505 t/h and a specific powerconsumption of the main drives (mill motor, mill fan and classifier) of 15,8 kWh/ mill is a vertical roller mill from are very satisfied with the Loesche LMmaster and the process experience theyare bringing into this solution.

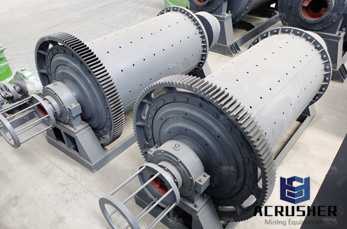

The Cement Plant Operations Handbook is a concise, mentioned in Chapter 3 for dry raw milling ball mills, vertical roller mills, roll presses, Horomill cement components to maintain deliveries during maintenance shutdowns and, if the market is cyclical,

cement plant. The paper also mill operations, inspections, process measurements, feed/product characteristics and grinding performance, Canada has developed a control strategy for ball mills which can maintain a mill production near optimum, with little operator intervention.

LM Vertical Mill Grinding System(Without Hot Air) Raw materials in the hopper are lifted by elevator and pass though airlock device, enter into the grinding chamber. Ground by the LM grinding mill, powders are collected and transported to silo. The advantages of this system are that it has simple structure, low investment and operation cost.

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw

As vertical mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise operating costs. The high energy efficiency is especially beneficial in countries with power generating capacity or where electricity availability is limited.

Buy raw mill for cement raw meal and other mineral raw materials grinding with good quality and reasonable price. Take action to buy now!

FL has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades. The OK mill has been FLs standard cement VRM since 1993. Since its introduction, the OK mill has proven to be the most efficient cement

Milling Equipment: cement plant vertical raw mill maintain stable operation A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial finished product can be

WhatsApp)

WhatsApp)