desing of mobil gold leaching plant

Lastest design China concrete batching plant for sale desing of mobil gold leaching plant|Manufacturer heavy. highway aggregate field,concrete mixing plant,dry mortar plant design gold extraction plant min.

WhatsApp)

WhatsApp)

Lastest design China concrete batching plant for sale desing of mobil gold leaching plant|Manufacturer heavy. highway aggregate field,concrete mixing plant,dry mortar plant design gold extraction plant min.

mobile gold leaching plant stone mining. mobile gold ore leaching plant #171; BINQ Mining. Copper Tailings Leaching Plant Zambia,Copper Smelting Machine. 12 Apr 2013

Desing Of Mobil Gold Leaching Plant. Desing of mobil gold leaching plant heap leach pad design h eap leaching has been applied to a number of different ores containing metals including gold silver copper nickel zinc and uranium the ore can be processed as coarse rock normally referred to as a dump leach or as a crushed ore in a heap leach. More

Leaching Tank Installation and Commission of Busolwa 1200TPD Gold CIL Plant, Xinhai Busolwa 1200TPD Gold CIL Plant is a rock gold ore processed by adopting t...

effects. Diagnostic leaching was used to show that mineralogy was not an important factor in the enhanced gold extraction in the presence of activated carbon for the ores. Kinetic models were developed for the leaching of gold from the ore, adsorption onto activated carbon and pregrobbing at the ore surface. A variable order empirical

copper heap leaching plant manufacturers stone crushers . copper heap leaching plant manufacturers stone crushers in kenya. Copper ore washing plant xsm is a leading global manufacturer of crushing and milling ilmenite ore processing plant layout chinese fabricators of doors in kenya iron ore consulmet consulmet offers a range of modular plants for the beneficiation of iron ore.

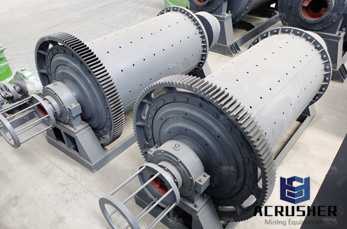

desing of mobil gold leaching plant. heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher,

Gold Extraction Equipment. Carbon Screen; Washing Thickener; Air Lifter; Leaching Agitation Tank; Zinc Powder Displacement Device; Desorption Electrolysis System; Mineral Processing EPC; Solutions; About; Contact; Home; Products; cip plant mining agitation leaching plant professional; cip plant mining agitation leaching plant professional

The process design of gold leaching and carboninpulp circuits contaminants. These are removed by thermal regeneration of the eluted carbon, typically in a rotary kiln at temperatures of 650750#176;C. Regeneration is carried out in a steam atmosphere to minimize carbon degradation due to oxidation. The eluted and regenerated carbon is screened at about

This plant processes 4 million tons of ore per year with an average gold content of ounces of gold per ton of ore. Approximately 85% of the gold is recovered in the plant. From the ball and/or autogenous mill, slurry is pumped to the CIL leach tanks where lime adjusts the pH, if necessary, and it is agitated for the desired period of time.

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

Gold Cyanide Solution (Leaching Gold With Cyanide) Since the 1890''s, cyanide has been used to recover gold from gold bearing ores. And today, over 115 years later, most of the worlds gold is recovered with cyanide playing a large part in the beneficiation of the yellow precious metal.

Gold recoveries equal to that of chemical leaching processes are achieved by the Modular Gold Plant. mechanical simplicity and ease of access to all components is at the core of the design of all Modular Gold Plants. are required for site assembly making the gold milling operation a fully mobile modular gold plant.

Gold leaching carbon in leach process is widely used in the newly built gold leaching plants in recent years and a lot of plants are changing into cil as well gold leaching cil process is suitable for the treatment of oxidized gold ore with low sulfur con,Desing of mobil gold leaching plant.

Desing Of Mobil Gold Leaching Plant. Design of mobile gold leaching plant chinagrindingmillt design of mobile gold leaching plant 28 may 2012 gulin supply mining and construction equipment for mineral handlinghe crushing, screening, washing,.

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

Leaching plants, faced with increased tonnage, coarse (up to 3/16 solids) feed, longer retention time, erosion, corrosion and the high cost of space, must be compact, simple and highly efficient. The engineer faced with the obvious economy of using a few large agitators compared to many smaller units must also evaluate the design factors which will prevent the settlingout of solids

Desing Of Mobil Gold Leaching Plant imsn. kappes, cassiday amp; assoc. reno mining metallurgy . the al hajal plant (also used at the hamd project) in saudi arabia is a complete plant for production of dore gold bars, mounted in a 6 meter (20 foot) container. the smelting furnace can be seen on the concrete slab on the right side of the photo. this size plant is ideal for heap leach tests or

Agitation capacity based on 36 to 48 hours of agitation time. Thickener area based on 6 to 7 square feet per ton of dry solids per 24 hours. Pregnant cyanide solution (Primary Thickener Overflow) is treated in a Precipitation System which includes: Clarifier, Vacuum Tank, Vacuum Pump, Clarifier Pump, Zinc Dust Feeder, Zinc Mixing Tank with Pump, and Precipitation Tank, Motors and Drives are

WhatsApp)

WhatsApp)