Ball mill understanding amp; optimisation | Mill (Grinding

Ball mill understanding amp; optimisation Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. mill

WhatsApp)

WhatsApp)

Ball mill understanding amp; optimisation Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. mill

Fives proposes the most adapted solution for wet product drying, according to the product and the specific needs of the installation: Typical dryers such as rotary kiln and rotary dryer for granular and medium size raw material. Ball mill inlet flash dryer for ball mill feed grainsize distribution from 0

Drying and grinding are generally being done in either air swept ball mill or a vertical mill. The selection of mill system will depend mostly on the factors like initial capital cost, drying and grinding capacity required, cost of energy (power) etc.

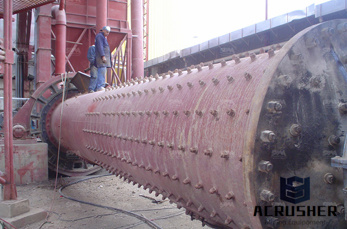

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either

The Mikro#174; UMP Universal Milling System is a compact, high speed impact mill capable of coarse granulation or fine size reduction with interchangeable rotor configurations. Mikro LGM#174; Long Gap Mill The Mikro LGM#174; Long Gap Mill is an air classifier mill that uses a combination of attrition and impact forces for fine size reduction down to D97 10 m.

#0183;#32;The structure of the ball mill is simple. The discharge port is hornshaped, and there is a screw device in it, which is convenient for discharging materials. The difference in working principle 1. Dry grinding Dry grinding means that when the ore is ground into the size we need, the powder will be brought out from the ball mill by the airflow.

Ball Mills Psp Eng. Assembly of a raw mill 216 54 x 11 m with predrying chamber 3D model of a raw mill Raw mill 216 54 x 11 m with a predrying chamber Example of a ow sheet of raw mill grinding circuit 2 4 6 8 1 ball mill 2 elevator 3 separator VTP 4 separating cyclone 5 mill fan 6 separator fan 7 clinker bin material 8 gypsum

Enhancing the capacity of largescale ball mill through. May 01, 2020 Too large a material ball ratio indicates too much ore in the mill, which might cause the mill to swell, and would affect the movement of grinding media and the circulation of ore in the mill, and also lower the mill capacity,.

Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary greatly within the ball charge.

#0183;#32;Rotary dryer has its applications in many industries like mine, building materials, cement, chemical, food and beverages, fertilizers and many more. In order to control temperature in rotary dryers, they are provided with thermocouples on the discharging and feeding proper temperature control, it is also provided with thermometers.

The vertical ball mill is used for the processing of highviscous premixed pastes, like chocolate, compound, cr#232;mes, nut and seedpaste. The continuous design vertical ball mill can be used in a 1 3 stage refining system, with 1 3 ball mills in a sequential row after the premixer.

Media and Product Ball Mill Loading Guide (Percentages are based on total volume of cylinder) NOTE: With media load at 50%, voids are created equal to 20% of cylinder volume. These voids are filled when product is loaded into the mill. Mills can be loaded by volume

WhatsApp)

WhatsApp)