Standard Operating Procedure () Milling Machine

Nov 02, 2009#0183;#32;MILLING MACHINE. STANDARD OPERATING PROCEDURE Keep all guards in place while operating the machine. While operating the milling machine allow no one else to

WhatsApp)

WhatsApp)

Nov 02, 2009#0183;#32;MILLING MACHINE. STANDARD OPERATING PROCEDURE Keep all guards in place while operating the machine. While operating the milling machine allow no one else to

Standard Operating Procedure for using the IDEAS lab milling machine Design Item to be Milled Ansoft Designer 1. From Ansoft Designer (Projectgt;Insert Planar EM Design to start, select any Duroid material) 2. If you need a complicated shape for your cutout outline, draw it on a different layer. 3.

Nov 02, 2009#0183;#32;MILLING MACHINE. STANDARD OPERATING PROCEDURE Keep all guards in place while operating the machine. While operating the milling machine allow no one else to touch it. Keep hands away from moving cutting tools. Do not make measurements of the stock while the milling machine is powered. Do not allow large quantities of chips to accumulate around the work piece or

JOB STEPS Ensure material to be machined is appropriate size and will mill safely. Secure material in jaws of vice (remove all debris from vice to ensure material is positioned accurately) and position tooling appropriately. Ensure correct cutting bit is selected and machine is set at correct speed for the material you are machining. (Always

Fix the stainless steel rotor and stator at a necessary gap, to obtain a smooth slurry or suspension. Fix the hopper, and if necessary circulating unit. Put ON the mains. Pass the slurry or suspension through the colloid mill and check the consistency. If not

Standard Operating Procedure () Milling Machine

Standard Operating Procedure (SOP) Milling Machine Keep all guards in place while operating the machine. While operating the milling machine allow no one else to touch it. Keep hands away from moving cutting tools. Do not make measurements of the stock while the milling machine is powered.

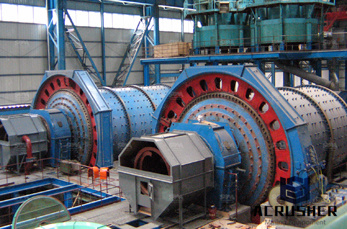

Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started. Check the ore slot feeder for obstruction or hangups. Check the ball mill belt feeder for undue buildup of material. Check oil level in ball mill lube oil tanks. Also, check grease level in the mill ring gear spray lube drum. Ensure that the

Standard Operating Procedure (SOP) Milling Machine Keep all guards in place while operating the machine. While operating the milling machine allow no one else to touch it. Keep hands away from moving cutting tools.

adequately trained in the following procedures and that these procedures are adhered to. Facility Managers are responsible for ensuring the quality of all feed and bedding, monitoring milling dates, and discarding any expired feed. 2. It is the responsibility of the animal care staff to read, understand, and follow the procedures outlined below

Standard Operating Procedure (SOP) Milling Machine UCLA STANDARD OPERATING PROCEDURE ''''. Keep all guards in place while operating the machine. While operating the milling machine allow no one else... Get Price

Standard Operating Procedure (SOP) Milling Machine Keep all guards in place while operating the machine. While operating the milling machine allow no one else to touch it. Keep hands away from moving cutting tools

Aug 23, 2020#0183;#32;A Standard Operating Procedure (SOP) is a document consisting of stepbystep information on how to execute a task. An existing SOP may need to just be modified and updated, or you may be in a scenario where you have

Inprocess Procedures. Blow off the machine thoroughly between cycles and measure every few parts to make sure they are being cut accurately. Check the tips of the tools and replace as necessary. Clean off the jaws every cycle.

Example Standard Operating Procedure Title:_SOP001 Milling Machine PI: Art Erdman Lab Location: Mayo G217 Issue Date: 11/11/13 Revision Date: NA Prepared by: Darrin Beekman Approved by: Hazard Identification: Physical Danger Exposure Assessment: Motions Rotating Motion In milling

Standard Operating Procedure (SOP) Templates for Word Plans When someone is looking to have a form made up that tells of the standard operating procedure for a specific situation, they need to have help in creating something that is going to clearly share all that they need to share.

BALL MILL STANDARD OPERATING PROCEDURE: SL NO PROCEDURES STATUS REMARK

O:Student Support and TrainingHealth and SafetySOP''sSOP_Milling 2. Operation: Keep clear of moving machine parts. Never leave the machine running unattended. Follow correct clamping procedures keep overhangs as small as possible and check work piece is secure.

Aug 07, 2020#0183;#32;quot;SOPquot; is generally understood to mean Standard Operating Procedure, but it has no official definition as far as the standard is concerned. In tiered (quot;pyramidalquot;) document systems, it normally refers to the second tierprocedures. The whole idea of

WhatsApp)

WhatsApp)